Cellophane Machinery /Start-up Cost:What will it cost to start that business?

Of course, you can’t know for sure, but you can work with reasonable estimates.

You can break down the problem into simple lists.

And work through the lists.

It’s always a guess—but you can make it a good educated guess. Here’s how.

Startup expenses are those expenses incurred before the business is running.

Get expert advice on becoming a successful business owner with BusinessHAB Business category! Our step-by-step articles can help you navigate the ins and outs of the business world, from forming a public limited company (PLC) to measuring company growth of an existing company. Learn how to avoid unionization of a company, identify industry trends, implement efficiency strategies, and more! You can request publication of your article for publication by sending it to us via our Email below. Get the 20 Best Strategized Fuel Tanker Business Plan

See also: 30 Bathroom Linen Retail Business in Nigeria

Many people underestimate startup costs and start their business in a haphazard, unplanned way.

This can work, but it is usually much harder.

Estimating realistic startup costs is one of the key elements of your financial plan.

Customers are wary of brand new businesses with makeshift logistics.

And you can’t figure out how to manage startup costs until you calculate them accurately.

Read also: 17 Tips to Start Handyman business in Nigeria

Cellophane Machinery /Start-up Cost

What are startup costs?

You should know that startup costs are not a universally accepted.

Or carefully defined financial concept.

Accountants and analysts disagree.

For planning and management purposes.

We define starting costs as expenses you incur and assets you need before you can launch the business.

See also: 32 hotel housekeeping and cleaning tips & tricks for 2019

Cellophane Machinery /Start-up Cost

Two essential lists:

Startup costs normally include startup expenses and startup assets:

- Startup expenses: These are expenses that happen before you launch and start bringing in any revenue. For example, many new companies incur expenses for legal work, logo design, brochures, location site selection and improvements, and other expenses. Startup expenses also include expenses such as rent and payroll that start before launch and continue from then on.

- Startup assets: Typical startup assets are cash (in the form of the money in the bank when the company starts), and in many cases, starting inventory. Other starting assets might be either current or long-term assets, such as equipment, office furniture, vehicles, and so on.

Turn to: 17 Tips to Start Incense Food Production Business in Nigeria

Cellophane Machinery /Start-up Cost

As the world is going corporate, the need for packaging is increasing every day.

Packaging improves image and branding of a product.

Hence the need for shopping bags.

Almost every business uses shopping bags these days ranging from supermarkets.

Eateries, banks (cash bags), boutique, and bookshop to road side shops.

Thereby creating large demand for the product.

Read on: 24 Tips to Open Living Room Furniture Showroom in Nigeria

Cellophane products enjoy both national and international patronage.

In fact, it is one of the fasted selling consumer goods in the country today.

This is because its demand has a relationship with the level of demand for other goods.

The product is demanded all year round.

And not affected by season; nevertheless.

It has a greater demand during the raining season

Read on: 19 Tips to Write Computer Sales Business Proposal in Ghana

As a matter of fact the capital involved depends largely on the financial capability of the investor.

If you have small capital, you can start with the locally fabricated machines.

Semi-automatic machinery.

Or better still you can start with buying the raw materials.

While the extrusion/blowing of the raw material.

Cutting, punching and printing aspect of the production process would be taken care of by other companies.

See also: Top 19 Agribusiness Proposal Writing Tips in Nigeria

The only thing to be done is marketing of the finished goods.

And a significant mark-up will still be achieved.

On the other hand, if you can afford the cost.

It is best to acquire a fully-automatic machine.

Which is much more efficient and profitable because aside your own productions.

You can as well get jobs from outside.

Read also: 50 Unique Hotel Business Idea Opportunities For 2019

Cellophane Machinery /Start-up Cost

The machines required to start nylon processing plant includes but not limited to:-

1. EXTRUDER BLOWING MACHINE: –

This is the machine which turns the raw materials (Master Berg, Escorene, DOW, B.A.S.F, etc) into a liquid form and later to polythene sheets in whatever color or thickness desired.

2. CUTTING MACHINE:-

This is the machine which cut the polythene into various sizes

3. PUNCHING MACHINE:-

This machine particularly punches holes of various shapes which will serve as handles.

The punching machine (foreign hydraulic) will cost you around N1 million.

While the local one will cost around N500, 000 – N800, 000.

This machine is used to create holes, handles and specific carrier shapes of the polythene.

The major raw materials are petroleum products and master Berg.

Master-Berg is the colour matter added to the cellophane by products to give its various colours.

The production process of cellophane sheet is simple but technical.

See also: 17 Tips to Open Textile Manufacturing Mini Company in Gambia

The raw material (either B.A.S.F or Escorene or DOW) is poured into the heating and melting unit of the extruder machine.

This is heated, melted and converted to a liquid substance.

Which is blown under pressure through a passage.

And simultaneously cooled in the process by an air generating apparatus.

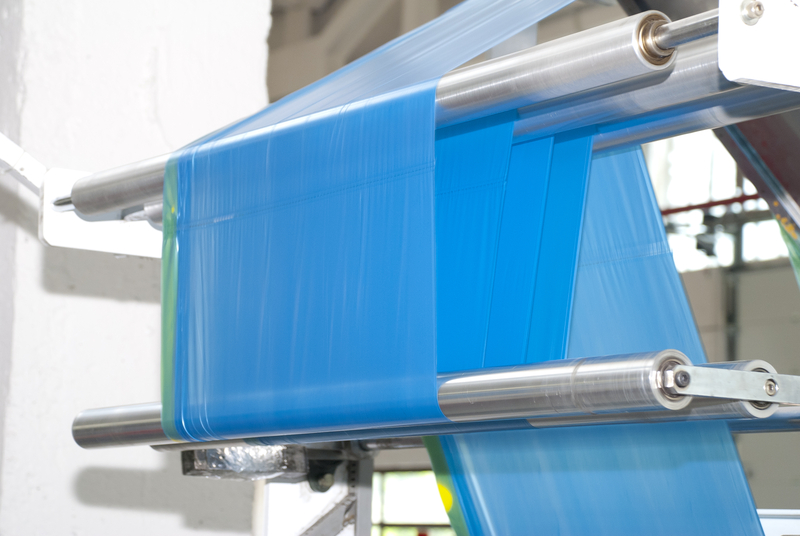

Producing cellophane sheets directed by a series of rollers.

Converting it into bales in the output unit of the extruder.

The sheets are now taken to cutting and sealing machine.

And subsequently to the handle-cutting machine.

See also: 10 Types Of Repair Business Idea / Opportunity in Nigeria

Cellophane Machinery /Start-up Cost

3. PRODUCTION PLAN

The location for cellophane plant could be sited anywhere.

As long as it meets relevant factory laws and regulations.

Except that if you are starting on a big scale.

Adequate provision must be made for the spaces to be occupied by the machines.

Depending on their sizes.

Otherwise, you might not really need a physical location.

If you are starting with little capital.

Just a call card and minimum capital of N50k-N100k.

Read on: 31 Reasons to open Fresh Coconut Retail Business in Nigeria

You are good to go.

The production process of cellophane shopping bags {the extrusion part only}.

The raw material is poured into a heating and melting unit of the extruding machine.

This is heated, melted and converted to a passage (extrusion).

And simultaneously cooled in the process by air generating apparatus.

What passes through the cooling chamber is the cellophane sheet.

Being directed by some rollers, converting it into bales in the output unit.

See also:9 Steps To Maintaining Washing Machine

Cellophane Machinery /Start-up Cost

In addition to location, you must ensure the area.

Where the cellophane factory is to be sited.

Experiences power supply at least averagely.

As this will reduce the cost of buying diesel, saves turnaround time.

And reduces wastage arising from intermittent power outage.

The finished product in cellophane processing is not a perishable good.

So it can be stored just anywhere that is cool.

But not in an inflammable area.

Because its raw material is a petrol-chemical by-product.

Read on: 24 Tips to Open Kitchen Appliances Showroom in Nigeria

Cellophane Machinery /Start-up Cost

4. CAPITAL EXPENSES

- FACTORY LOCATION

- EXTRUDER/BLOWER :-

- Foreign (dual Hd /Ld Extruder blower) N4,950,000M

- Local (Hd or Ld) range is between N1.5 –N2.0M

5. CUTTING AND SEALING MACHINE

Nylon Cutting Machine:

This machine is responsible for cutting the polythene into the various sizes which are needed.

The nylon cutting machine (foreign double checker machine) should cost you around N3 million or more

While the local one would cost you about N1 million or more.

- Double decker machine (foreign) N2,180,000M

- Local machines ranges between N0.7M-N1.2M

See also: 24 Tips to Open Huawei Products Showroom in Nigeria

6. PUNCHING MACHINE

- Foreign (Hydraulic ) N720k-N1.2M

- Locally fabricated N400K-N650K

7. PRINTING

Printing Machine:

This machine is for creating designs on the nylon sheets.

The high definition of this machine will cost you around N1.5 million – N2.5 million.

While the low definition will cost you around N1.5 million.

- High Definition (one or two color) price ranges N1.5M-N2.5M

- Low Definition (one or two color) price ranges N1.0M-N1.5M

N.B: Prices of machinery and materials are subject to change by the manufacturers.

Therefore the prices given here are is quoted when the research was conducted.

- Foreign (Hydraulic ) N720k-N1.2M

- Locally fabricated N400K-N650K

Read on: Top 24 Infinix Products Showroom in Nigeria

Cellophane Machinery /Start-up Cost

8. OPERATIONAL EXPENSES

RAW MATERIALS

- Low definition material per bag (25kg) N7,200

- High Definition material per bag (25kg) N8,200

- Exxon-Mobil per bag (25kg) N8,350

- Master Berg per kilo N700-N1,000 (depending on colors)

Cellophane Machinery /Start-up Cost

9. LABOUR

- Operator man (@ N1,875 per/day for 24 days) N45,000

- Extrusion, cutting and punching of 7 bundles/25kg N1,500

- Transportation of raw materials and finished goods N5,000

- Marketers per day(N0,000)/per month N35,000

- Utilities N10,000

- Promotions N20,000

10. Extruder Blowing Machine:

This machine is responsible for producing the cellophane.

By converting the raw materials required for the process first into liquid.

Then to polythene sheets.

And which can then be moulded into the desired density and colour.

The extruder blowing machine (foreign) will cost you about N4 million – N5 million.

While the local one could be gotten for around N1 million – N5 million.

See also: 30 Tips to Open Tablet Accessories Retail Business in Nigeria

Cellophane Machinery /Start-up Cost

11. Others include:

- A.S.F and,

- Master Berg

The Master Berg is the colouring agent for producing different colours of nylons.

The Dow or B.A.S.F or Escorene is what is poured into the heating unit of the extruder machine.

Ideally, for every 7 bales of polyethylene sheets produced with 2 bags of 25kg of Dow or Escorene and 8kg of Master Berg, you should get about 1,000 pieces of 50 x 40 x 0.45 shopping bags.

Turn to: 17 Top Bounties Business Tips In Nigeria

Cellophane Machinery /Start-up Cost

There are various market prices of Nylon Polythene bags depending on some factors such as:

Thickness

Sizes

Quantities

Markets

Buyers

Payment terms

Transportation cost

Frequency of orders and other variables as situation demands.

The prices I have given here is not to be taken hook.

Line and sinker rather a would be investor should conduct adequate market research.

Feasibility and viability studies,mathematical project analysis and financial management of the business.

See also:9 Top Washing Machine Business Guides in Nigeria

Cellophane Machinery /Start-up Cost

12.Market prices of Nylon.

N2,000/pack of Fashion (0.6/0.7mm)

N3,500/pack of fashion (0.8mm)

N2,000/pack of stationeries (0.6mm)

N3,500/pack of stationeries(0.8mm)

N10,000/pack of snacks (0.6mm)

N1,500/pack of singlet (0.2mm)

N3,500/pack of poly-thick (0.8mm)

13.Carryout a Market Survey

Before you even venture into the nylon production business.

It is pertinent you carry out a thorough market survey to determine who your target market is.

The market survey must be done within the area you decide to site your nylon production business.

In most places in Nigeria, you will likely have the following groups make up the target market for nylon production businesses:

- Pharmacies

- Water production companies

- Eateries and restaurants

- Traders

- Hospitals

- Bakeries

- Supermarkets

- Laundry

- Fashion stores

- Schools

N.B: Before embarking on production and supply of cellophane materials to your clients.

Ensure due diligence in areas highlighted above.

Leave a Reply